Continuous Casting Machine (CCM) Spray Nozzle Manufacturer, Supplier

At SPRAYNOZ Technologies Pvt. Ltd., we specialize in delivering high-performance spray nozzles designed for continuous casting machines (CCM). Our innovative solutions are engineered to enhance the efficiency, precision, and longevity of the casting process, ensuring superior quality and productivity for your operations.

Key Features :

Precision Engineering: Our CCM spray nozzles are crafted with meticulous precision to deliver uniform and consistent cooling, crucial for the continuous casting process.

High-Quality Materials: Made from premium materials, our nozzles are designed to withstand high temperatures and harsh environments, ensuring durability and long service life.

Optimized Spray Patterns: Engineered to provide optimal spray coverage, our nozzles help in maintaining the desired cooling rates, minimizing thermal stress and preventing defects.

Easy Maintenance: Designed for easy installation and maintenance, our spray nozzles help reduce downtime and operational costs.

Applications :

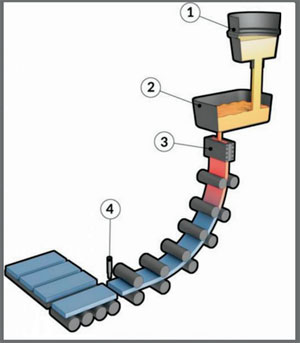

Our CCM spray nozzles are suitable for various stages of the continuous casting process, including:

Primary Cooling: Ensuring uniform cooling of the molten metal as it solidifies in the mold.

Secondary Cooling: Providing precise cooling to maintain the desired temperature gradient, preventing cracks and defects.

Tertiary Cooling: Fine-tuning the cooling process to achieve the final product specifications.

Why Choose SPRAYNOZ Technologies?

Expertise and Experience: With years of experience in the industry, we understand the unique challenges of continuous casting and offer solutions tailored to meet your specific needs.

Innovative Solutions: Our commitment to research and development ensures that we stay at the forefront of technology, offering cutting-edge products that enhance your operational efficiency.

Customer Support: We provide comprehensive support, from product selection to installation and maintenance, ensuring seamless integration into your production line.

Nowadays, the demand for steel is getting more and more specific (like high tensile strength steel, advanced high-strength steel, etc.). The market worldwide is split between emerging economies where the demand and production are growing. Therefore, it is becoming crucial for steelmaking plant to stay competitive, control / reduce their cost, and increase productivity to fulfill the growing demand. When it comes to control the quality of the cast steel product (end result), the secondary cooling for continuous casting machines is the most crucial step of the process.

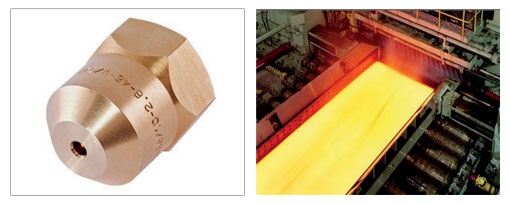

CCM SPRAY NOZZLE:

It is a device used to control the spray distribution and spray impact to ensure an optimal and uniform cooling.

FEATURE OF STPL CCM SPRAY NOZZLES:

• Generate a uniform cooling

• Reduce surface cracking

• Maintain a satisfactory surface temperature profile

• Minimize or eliminate surface and internal defects in the cast product

• Control water consumption

APPLICATION OF CCM SPRAY NOZZLES:

• Continuous casting machine for secondary cooling.